Standard hood mounted filtration cabinet with high-efficiency carbon

filter. Capture, contain and filter within electronic design and rework,

dental/ medical labs, pharmaceutical labs, design, technology and

science in education and more...Applications include the filtration of

fumes, vapour and particulates emanating from

: Spray adhesives, conformal coatings and paints, monomers, hazardous

powders and particulates, resins, sealants, solders, light grinding

particles, organic solvents and cleaners etc.

Operation

All filtration and extraction systems carry a 1 Year warranty, are

quiet in operation and can be assembled in seconds. Place onto a desk,

bench or trolley and then simply plug in and switch on. Handling and / or use of potentially harmful substances is carried out

within the hood enclosure in front of the intake filter area. Cleaned

air is vented to the top rear of the units. For artwork applications, standard A2 drawing boards can be placed

within the hood enclosure. The boards fit at an angle for efficient over spray capture.

Filtration

The particulate (intake) filter is a three stage graduated fibre filter

with a high dust holding capacity for long life. Filtration to 5

micron particles. (Optional EPA filters available). This is followed by a

high grade bonded carbon filter. Through the process of filtration, adsorption and dilution, operator

exposure to potentially hazardous substances is vastly reduced or

eliminated.

These units are designed for immediate operator protection from

concentrations of airborne contaminants whereby all gases, fumes,

vapours and particulates within the hood enclosure are filtered and

cleaned air is exhausted to the top rear of the cabinet.

Demonstrating adequate control of the risks to the health of employees

students and the general public, from dusts, powders, mists, fumes and

vapours is the fundamental requirement of the

Control of Substances Hazardous to Health (CoSHH).

Applications include the filtration of fume, vapour and particulates emanating from monomers, adhesives, hazardous powders/particulates, conformal coatings, resins, sealants, solders, light grinding particles and dusts, organic solvents etc.

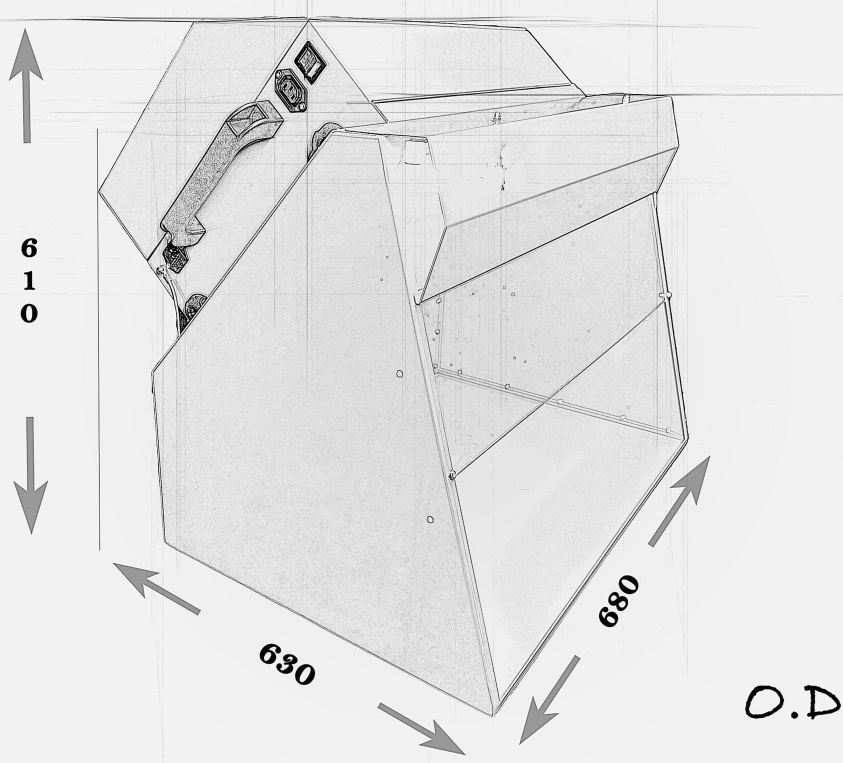

Part ID: T660H-C

Size: 680 x 610 x 630mm

Fan Motor Spec: 230V 50Hz 105W

Air Volume at Free Air: 355 m3/hr

Air Velocity at Filter Face: 0.50 m/sec

Air Velocity at Hood Face: 0.50 m/sec

Noise Level: 60 dB (A)

Weight: 35 kg

Commodity Code: 84213925

Warranty: 1 Year

Approvals: CE, REACH

* Systems are built to order.

Adhesive Dispensing Ltd provide a wide

range of equipment options for dispensing almost all assembly fluids - from

watery liquids, solvents, primers and activators through to thick pastes,

sealants, silicones, gels and epoxies.

- Part ID: T660H-C

- Fan Motor Spec: 230V 50Hz 105W

- Air Volume at Free Air: 355 m3/hr

- Air Velocity at Filter Face: 0.50 m/sec

- Air Velocity at Hood Face: 0.50 m/sec

- Noise Level: 60 dB (A)

- Weight: 35 kg

Fan/filter casing (steel construction finished in dove grey) - clear PETG folding plastic fume shield - particulate (Intake Filter) - bonded carbon filter - centrifugal blower, external rotor motor type brushless, UL, VDE and CSA approved - sealed electrical wiring and switch, downstream of filters.

*110V 60Hz version available if required.

All WS filtration and extraction systems carry a lifetime warranty, are quiet in operation and can be assembled in seconds. Place onto a desk, bench or trolley and then simply plug in and switch on.

The folding PETG shield can be stored if not required thus reducing the unit footprint considerably. Handling and / or use of potentially harmful substances is carried out in front of the intake filter area. Cleaned air is vented to the top rear of the units.

|